Unveiling the Magic Behind Augumenta’s AR accuracy: Camera Calibration in Smartglasses

Introducing camera calibration and its importance in high-accuracy augmented reality

We had the privilege of meeting a knowledgeable and international crowd in the Hannover Messe 2018 expo and showcase the power of AR joining forces with an Industrie 4.0 platform.

The last full week of April brought over 200 000 people to visit the HannoverMesse 2018 expo to see, feel and talk about the integrated industry. According to Messe statistics, 70 000 of the visitors and 65% of the over 5000 exhibitors were from outside of Germany. We had the privilege of meeting a part of this knowledgeable and international crowd and showcase the power of AR joining forces with an Industrie 4.0 platform. What we learned from our expo visitors: improving the efficiency of production processes is the number one reason why enterprises are looking into AR.

Augumenta smartglasses AR applications were displayed at the expo together with the solutions of Connected Production, a joint project of three German enterprises; Vision Lasertechnik, Bluebiz and Uniorg. The project aims at helping German SMEs to successfully take their steps into digitized industry. The Connected Production’s Smart Factory platform integrates solutions from sensors to applications and creates a connected, transparent and controllable production system for enterprises. Simply put, it is all about information and our AR apps play the key role in making that information visible and actionable for the workers on the shop floor.

Great ideas often come inadvertently. Our first encounter with Connected Production partners took place rather late considering the Messe schedule, but we quickly discovered the mutual benefits of joining our efforts. We had only a few weeks of time to come up with the final demos and integrate them into the Smart Factory configuration presented at the stand. Once we got started the actual development of the applications took almost no time, it was a matter of days. This was due to the fact that our software already has all the pieces, like support to the common industrial protocols, there and ready. As the Smart Factory platform is also designed to use open and flexible interfaces and to support IoT protocols like MQTT, getting these two to talk to each other was almost surprisingly fast. This was a perfect showcase on how IoT platforms and AR solutions work together at their best.

We had two simple use cases and two apps to demonstrate AR in industrial use:

1) SmartAlert showing the critical production line data. A visitor could see the status and alerts related to a laser engraving robot that was marking pens for visitors on request. Visitors wearing monocular smartglasses could see was the robot running or idle, the state and number of the order, the amount of pens and cases in the storage and the actual energy consumption of the robot all in real time. If the storage was running low the display would flash an alert asking the user to check the number of items.

The robot was very entertaining, the Messe visitors adored it. It was also very competent in proving the point of platforms and AR working together in making sure production processes are running fluently. The hardworking robot emptied the storage repeatedly and gave concrete examples about how to prevent the costly downtime of production lines.

2) SmartPanel for IoT data access and machine control. A user equipped with smartglasses was able to see the status of a virtual CNC machine and a smart storage box holding the produced items. If a box was out of place the system would stop the machine and alert the user, who could then restart the process with virtual controls. The app showed how a worker on the shop floor can interact with key production processes very flexibly, securely and always in time.

The lead theme of the expo was integrated industry – connect & collaborate. All key industrial technologies and the latest know-how were present at the event. You could pick up a trend or two at the expo. From our / the AR point of view, the most interesting were:

Platforms and digitization strategy i.e. the abundant presence of service providers with products defined as IoT, Industry 4.0 or Smart Factory platforms, as well as the presence of consortia and networks with platforms to support the digitization efforts of enterprises.

There were a convincing number of AR solutions and devices present at the expo.

These two are connecting now rapidly as the service providers are looking for to create a more holistic offering to their customers. The terms IioT or Industrie 4.0 or its variations are not exactly interchangeable synonyms, but the basis of all of the terms lies in machines, analytics and people all getting tied together. It is all about information and AR is the factor making that information tangible and actionable. Like our partners at the Connected Production project said: “It will be more and more important to get the required information in time and on place”.

For the majority of Messe visitors we met, AR technology wasn’t just another interesting trick to see at the expo. Instead, they already had some use cases or clear problems in mind and wanted to know how AR could be used to help. It was truly encouraging to see that people have started to take industrial AR as we’ve seen it all along, a tool that is there to solve your problems today.

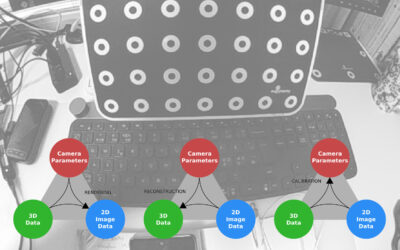

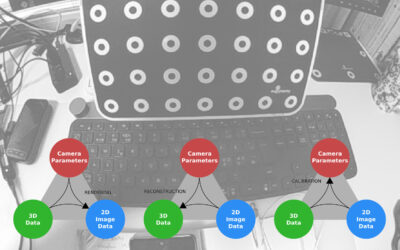

Introducing camera calibration and its importance in high-accuracy augmented reality

The eye box is the secret behind good AR UX. Discover what it is and how to take full advantage of this hidden smartglasses spec

How hundreds of millions can be saved every year by large logistics operations thanks to smartglasses and SmartMarkers.

How millions can be saved every year by introducing SmartPanel and smartglasses to reduce airframe weight, shorten idle time and shrink ground crews.