Unveiling the Magic Behind Augumenta’s AR accuracy: Camera Calibration in Smartglasses

Introducing camera calibration and its importance in high-accuracy augmented reality

With COVID-19 pandemic, there’s no other option but to digitize operations and find ways to keep working remotely. There are tools and help available for that.

One of the major implications of this very strange first half of 2020 is that the interest in digital solutions has skyrocketed: companies need to find new ways to keep their operations running with the travel and other restrictions at hand. That applies to us all.

The Augumenta team develops wearables solutions that are used also for remote working and learning use cases. Our own working methods have enabled remote work since the very beginning of the company as the members are scattered around the globe in several locations and have always had the option of working from home. We have overcome challenges caused by different time zones and learned how to share and prioritize and support others in work tasks remotely.

Having said that, we acknowledge that we face the same challenges as any other company during these times. We need to find new ways to collaborate with our customers on industrial augmented reality projects. Like most of you there, we cannot send our experts directly to customer locations to start projects and deliver solutions, and presenting your products entirely and only online is challenging. But we would like to encourage you, things can be done differently. There are ready-made solutions to support your experts in home offices and out there on the field.

In maintenance and repair, remote support with smartglasses and augmented reality have already a proven track record, and without a doubt helps save time and improve efficiency even during normal times. In manufacturing, the use cases expand into remote monitoring and machine control improving for example safety or uptime numbers. In training, smartglasses provide a tool for knowledge transfer and remote/independent learning. In fact, if there’s a need for any kind of support from an expert to another person working or learning in any field of industry, deploy smartglasses and AR apps.

With smartglasses and AR, you can improve the capabilities of workers to achieve things independently and even handle jobs that are not within their usual scope of tasks. This helps when there’s a shortage of skilled people available for certain tasks and experts can’t travel. Well-planned instructions and task lists with rich content that you can easily access while you work make practically any of us a semi-expert in many areas. If instructions don’t suffice a remote expert on the other side of a live video call that is sharing the same view gives you options to continue for example installation or repair projects that otherwise could significantly delay or not take place at all.

Learning-by-doing is the most efficient method of learning new tasks. Easy-to-use smartglasses apps and an experienced teacher giving remote advice is a highly efficient way of training new future experts, especially when you can’t be physically present in the same room. Smartglasses make a great tool for knowledge transfer. In simplest forms, they let an expert document the process of completing tasks correctly and share the result with less experienced colleagues.

With the right kind of devices and wearable apps accessing real-time IoT data, you can monitor and control processes and machines independent from your location. You don’t have to be in the control room or near a machine to get the alerts and notifications or the relevant values that you need to oversee a process. You can keep on working with other things/focus on fixing that one thing, and still rely on being notified of any upcoming issue requiring your attention. This makes a big difference if there’s a shortage of workforce and responsibilities need to be shared with utmost care so that those few capable can make sure all operations are running safely.

Today, the devices and applications can be controlled hands-free. This addresses also the problem of being able to work hygienically. You do not need to touch anything to get data in front of your eyes, control processes, or to document things. You can simply use gestures or voice to tell the device what to do. Tap air, not a keyboard.

In Augumenta, we’re used to dealing with industrial manufacturing, maintenance, and training people in those fields but the benefits of smartglasses and AR apply to any other industry area – including the medical field. Smartglasses can help medical staff, and not only now with their huge effort to take care of all the patients in the current situation, but also in the future by helping them to get the needed information in front of their eyes.

We cannot rely on going back to the old way of doing things once all of this is over, that’s for sure. There are lots of changes that stay and must stay permanent, how we work will affect the productivity and also sustainability of our operations. If you haven’t yet done it, now there’s no other option but to digitize operations. We’d like to emphasize that there are tools and help available. We are most certainly having a bunch of applications that might help many of you and there’s quite a number of fellow AR companies with ready-made solutions available on the market. You can find a lot of information from the AREA organisation’s website.

and would be privileged to share some of the learning we’ve picked up along the way. Please, don’t hesitate to

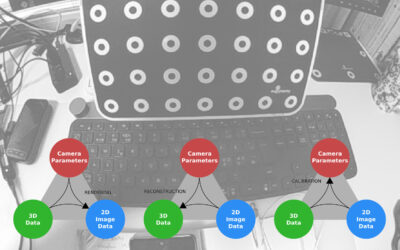

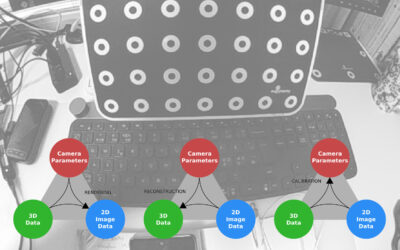

Introducing camera calibration and its importance in high-accuracy augmented reality

The eye box is the secret behind good AR UX. Discover what it is and how to take full advantage of this hidden smartglasses spec

How hundreds of millions can be saved every year by large logistics operations thanks to smartglasses and SmartMarkers.

How millions can be saved every year by introducing SmartPanel and smartglasses to reduce airframe weight, shorten idle time and shrink ground crews.